Themotashaft ndi yopanda kanthu, yokhala ndi mphamvu yabwino yotaya kutentha ndipo imatha kulimbikitsa kupepuka kwamota.Kale, ma shaft a mota anali olimba kwambiri, koma chifukwa chogwiritsa ntchito ma shaft a mota, kupsinjika nthawi zambiri kunkayang'ana pamwamba pa shaft, ndipo kupsinjika pakati pa shaft kunali kochepa. Malinga ndi momwe zimakhalira zopindika komanso zozungulira za makina azinthu, gawo lamkati la shaft linkagwira ntchito.motaMzere wa shaft unadulidwa bwino, ndipo panafunika dayamita yaying'ono yakunja kuti gawo lakunja liwonjezeke. Mzere wa shaft wopanda kanthu ukhoza kukwaniritsa ntchito yofanana ndi shaft yolimba, koma kulemera kwake kumatha kuchepetsedwa kwambiri. Pakadali pano, chifukwa cha kutseguka kwamotaMthunzi, mafuta ozizira amatha kulowa mkati mwa shaft ya mota, zomwe zimapangitsa kuti kutentha kusamayende bwino komanso kukonza bwino kutentha. Malinga ndi momwe zinthu zilili panopa, ubwino wa ma shaft a hollow motor ndi waukulu. Njira zopangira ma shaft a hollow motor makamaka zimaphatikizapo kuyika ma solid shaft hollowing, welding, ndi integrated forming, zomwe zimagwiritsidwa ntchito kwambiri popanga ma welding ndi integrated forming.

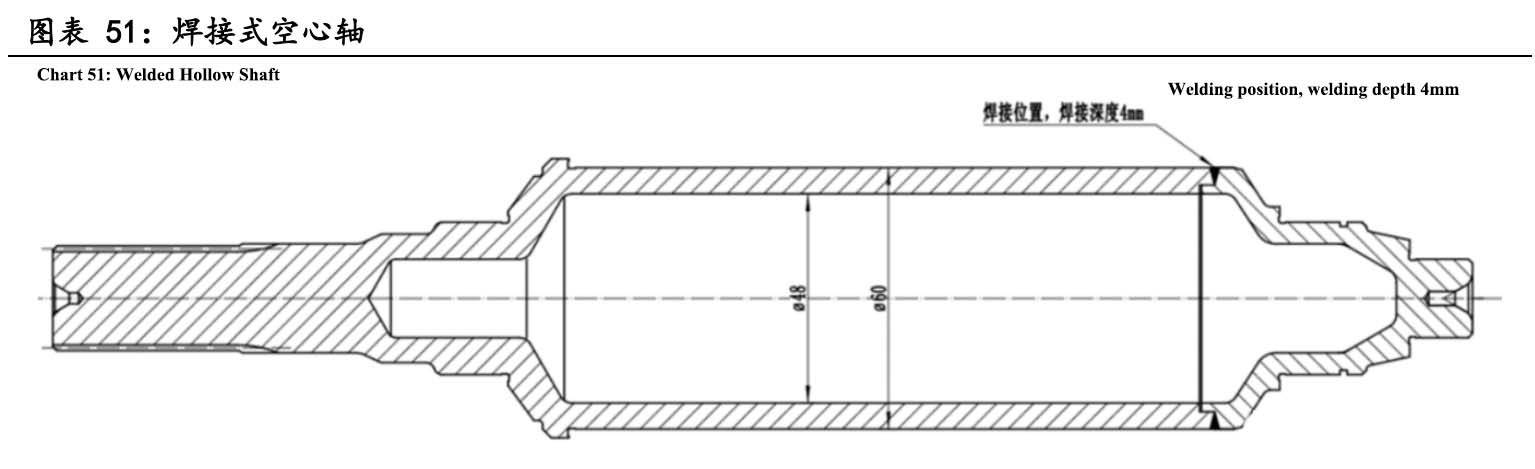

Shaft yolumikizidwa yokhala ndi dzenje lopindika imapezeka makamaka kudzera mu extrusion forming kuti ipange dzenje lamkati lopindika la shaft, kenako nkupangidwa ndi makina ndikuyiyika kuti ikhale mawonekedwe. Pogwiritsa ntchito extrusion molding, kusintha kwa mawonekedwe a dzenje lamkati ndi kapangidwe ka chinthucho ndi zofunikira za mphamvu kumasungidwa momwe zingathere. Kawirikawiri, makulidwe oyambira a khoma la chinthucho amatha kupangidwa pansi pa 5mm. Zipangizo zolumikizira nthawi zambiri zimagwiritsa ntchito butt friction welding kapena laser welding. Ngati butt friction welding ikugwiritsidwa ntchito, malo a butt joint nthawi zambiri amakhala pafupifupi 3mm welding protrusion. Pogwiritsa ntchito laser welding, kuya kwa welding nthawi zambiri kumakhala pakati pa 3.5 ndi 4.5mm, ndipo mphamvu ya welding ikhoza kutsimikizika kuti ndi yayikulu kuposa 80% ya substrate. Ogulitsa ena amatha kufikira mphamvu zoposa 90% ya substrate kudzera mu njira zowongolera zovuta. Pambuyo poti welding ya hole shaft yatha, ndikofunikira kuchita mayeso a ultrasound kapena X-ray pa microstructure ndi weld quality ya malo owetera kuti muwonetsetse kuti zinthuzo zikugwirizana.

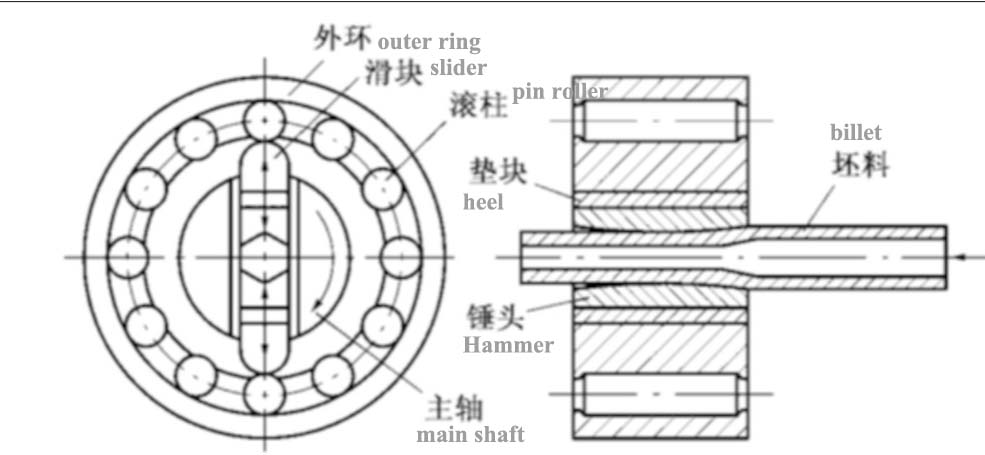

Shaft yopangira yopanda kanthu imapangidwa makamaka ndi zida zakunja pamalo opanda kanthu, zomwe zimathandiza kuti gawo lamkati likwaniritse mwachindunji dzenje lamkati la shaft. Pakadali pano, radial forging ndi rotary forging zimagwiritsidwa ntchito kwambiri, ndipo zidazo zimatumizidwa makamaka kunja. Radial forging ndi yodziwika bwino pazida za kampani ya FELLS, pomwe rotary forging ndi yodziwika bwino pazida za kampani ya GFM. Radial forging nthawi zambiri imachitika pogwiritsa ntchito nyundo zinayi kapena kuposerapo zofanana pafupipafupi kuposa 240 blows pamphindi kuti ikwaniritse kusintha pang'ono kwa blank ndi direct hollow tube blank forming. Rotary forging ndi njira yokonzera mitu yambiri ya nyundo molingana mbali yozungulira ya billet. Mutu wa nyundo umazungulira mozungulira axis uku ukuchita radial high-frequency forging pa workpiece, kuchepetsa kukula kwa billet ndikufalikira mozungulira kuti mupeze workpiece. Poyerekeza ndi shafts zachikhalidwe zolimba, mtengo wopanga ma integrated folded hollow shafts udzawonjezeka ndi pafupifupi 20%, koma kulemera kwa ma motor shafts nthawi zambiri kudzachepetsedwa ndi 30-35%.

Nthawi yotumizira: Sep-15-2023