Zinthu zomwe zimakhudza kugwiritsa ntchito chitsulo

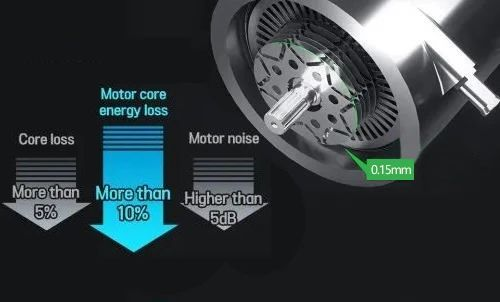

Kuti tifufuze vuto, choyamba tiyenera kudziwa mfundo zoyambira, zomwe zingatithandize kumvetsetsa. Choyamba, tiyenera kudziwa mfundo ziwiri. Choyamba ndi kusinthana kwa maginito, komwe, mwachidule, kumachitika mkati mwa chitsulo cha transformer ndi m'mano a stator kapena rotor a mota; Choyamba ndi mphamvu ya maginito yozungulira, yomwe imapangidwa ndi stator kapena rotor joko la mota. Pali zinthu zambiri zomwe zimayambira pa mfundo ziwiri ndikuwerengera kutayika kwa chitsulo kwa mota kutengera mawonekedwe osiyanasiyana malinga ndi njira yothetsera yomwe ili pamwambapa. Mayeso awonetsa kuti mapepala achitsulo a silicon amasonyeza zochitika zotsatirazi pansi pa maginito a zinthu ziwiri:

Ngati kuchuluka kwa maginito kuli pansi pa 1.7 Tesla, kutayika kwa hysteresis komwe kumachitika chifukwa cha maginito ozungulira kumakhala kwakukulu kuposa komwe kumachitika chifukwa cha maginito osinthasintha; Ngati kuli kokwera kuposa 1.7 Tesla, zosiyana ndi izi. Kuchuluka kwa maginito a flux a injini nthawi zambiri kumakhala pakati pa 1.0 ndi 1.5 Tesla, ndipo kutayika kwa hysteresis yozungulira yofanana ndi pafupifupi 45 mpaka 65% kuposa kutayika kwa hysteresis yosinthasintha.

Zachidziwikire, mfundo zomwe zili pamwambapa zimagwiritsidwanso ntchito, ndipo sindinatsimikizire ndekha. Kuphatikiza apo, mphamvu ya maginito mu chitsulo ikasintha, mphamvu yamagetsi imayambitsidwa mkati mwake, yotchedwa eddy current, ndipo kutayika komwe kumachitika chifukwa chake kumatchedwa kutayika kwa eddy current. Pofuna kuchepetsa kutayika kwa eddy current, chitsulo cha injini nthawi zambiri sichingapangidwe kukhala chipika chonse, ndipo chimayikidwa mozungulira ndi mapepala achitsulo otetezedwa kuti alepheretse kuyenda kwa ma eddy currents. Njira yeniyeni yowerengera kugwiritsa ntchito chitsulo sidzakhala yovuta pano. Njira yoyambira ndi kufunika kwa kuwerengera kwa Baidu iron chitsulo kudzakhala komveka bwino. Zotsatirazi ndi kusanthula kwa zinthu zingapo zofunika zomwe zimakhudza kugwiritsa ntchito kwa chitsulo, kuti aliyense athenso kutsogolera kapena kubwerera kumbuyo kuzindikira vutoli mu ntchito zogwirira ntchito zaukadaulo.

Pambuyo pokambirana zomwe zili pamwambapa, n’chifukwa chiyani kupanga sitampu kumakhudza kugwiritsa ntchito chitsulo? Makhalidwe a njira yobowola amadalira kwambiri mawonekedwe osiyanasiyana a makina obowola, ndipo amazindikira njira yobowola yofanana ndi mulingo wopsinjika malinga ndi zosowa za mitundu yosiyanasiyana ya mabowo ndi mipata, motero kuonetsetsa kuti malo opsinjika osaya kwambiri ozungulira mphepete mwa lamination ndi otani. Chifukwa cha ubale pakati pa kuya ndi mawonekedwe, nthawi zambiri imakhudzidwa ndi ngodya zakuthwa, mpaka kufika poti kuchuluka kwa kupsinjika kwakukulu kungayambitse kutayika kwakukulu kwa chitsulo m’malo opsinjika osaya, makamaka m’mphepete mwa shear yayitali mkati mwa lamination. Makamaka, zimachitika makamaka m’dera la alveolar, lomwe nthawi zambiri limakhala malo ofufuzira mu kafukufuku weniweni. Mapepala achitsulo a silicon otsika kwambiri nthawi zambiri amatsimikiziridwa ndi kukula kwakukulu kwa tirigu. Kukhudzidwa kungayambitse ma burrs opangidwa ndi ma shear odulidwa m’mphepete mwa pepala, ndipo ngodya ya kukhudzidwa ikhoza kukhala ndi zotsatira zazikulu pa kukula kwa ma burrs ndi malo osinthika. Ngati malo opsinjika kwambiri afalikira m’mphepete mwa deformation zone mpaka mkati mwa zinthuzo, kapangidwe ka tirigu m’malo awa mosakayikira kadzasintha, kupotoka kapena kusweka, ndipo kutalika kwakukulu kwa malire kudzachitika motsatira njira yong’ambika. Pakadali pano, kuchuluka kwa malire a tirigu m'dera lopsinjika komwe kumayendetsedwa ndi shear kudzawonjezeka mosalekeza, zomwe zimapangitsa kuti chitsulo chitayike kwambiri m'derali. Chifukwa chake, pakadali pano, zinthu zomwe zili m'dera lopsinjika zitha kuonedwa ngati zinthu zotayika kwambiri zomwe zimagwera pamwamba pa lamination wamba m'mphepete mwa impact. Mwanjira imeneyi, chokhazikika chenicheni cha zinthu zam'mphepete chitha kudziwika, ndipo kutayika kwenikweni kwa m'mphepete mwa impact kumatha kudziwikanso pogwiritsa ntchito chitsanzo cha iron loss.

1. Mphamvu ya Annealing Process pa Kutayika kwa Iron

Mphamvu ya kutayika kwa chitsulo imapezeka makamaka m'mapepala achitsulo a silicon, ndipo kupsinjika kwa makina ndi kutentha kumakhudza mapepala achitsulo a silicon ndi kusintha kwa makhalidwe awo enieni. Kupsinjika kwina kwa makina kumabweretsa kusintha kwa kutayika kwa chitsulo. Nthawi yomweyo, kuwonjezeka kosalekeza kwa kutentha kwamkati mwa mota kudzathandizanso kuti pakhale mavuto otayika kwa chitsulo. Kutenga njira zogwirira ntchito zochotsera kupsinjika kwina kwa makina kudzakhala ndi phindu pochepetsa kutayika kwa chitsulo mkati mwa mota.

2. Zifukwa zotayikira kwambiri mu njira zopangira

Mapepala achitsulo a silicon, monga chinthu chachikulu cha maginito cha ma mota, amakhudza kwambiri magwiridwe antchito a mota chifukwa chotsatira zofunikira pa kapangidwe kake. Kuphatikiza apo, magwiridwe antchito a mapepala achitsulo a silicon a mtundu womwewo amatha kusiyana ndi opanga osiyanasiyana. Posankha zipangizo, kuyesetsa kuyenera kupangidwa posankha zipangizo kuchokera kwa opanga abwino achitsulo cha silicon. Pansipa pali zinthu zina zofunika zomwe zakhudza kugwiritsa ntchito chitsulo zomwe zakumana nazo kale.

Chitsulo cha silicon sichinatenthetsedwe kapena kukonzedwa bwino. Vuto lamtunduwu limatha kupezeka panthawi yoyesa mapepala a silicon, koma si opanga magalimoto onse omwe ali ndi chinthu choyesera ichi, ndipo vutoli nthawi zambiri silidziwika bwino ndi opanga magalimoto.

Kuteteza kowonongeka pakati pa mapepala kapena ma circuit afupi pakati pa mapepala. Vuto lamtunduwu limachitika panthawi yopanga maziko achitsulo. Ngati kupanikizika panthawi yopaka maziko achitsulo kuli kokwera kwambiri, zomwe zimapangitsa kuti chitetezo chiwonongeke pakati pa mapepala; Kapena ngati ma burrs ndi akulu kwambiri ataponyedwa, amatha kuchotsedwa powapukuta, zomwe zimapangitsa kuti chitetezo chiwonongeke kwambiri pamwamba pa malo opopera; Pambuyo poti chitsulo chachitsulo chatha, mpata suli wosalala, ndipo njira yoperekera imagwiritsidwa ntchito; Kapenanso, chifukwa cha zinthu monga stator bore yosafanana komanso kusakhazikika pakati pa stator bore ndi mlomo wa mpando wa makina, kutembenuza kungagwiritsidwe ntchito pokonza. Kugwiritsa ntchito kwachikhalidwe kwa njira zopangira ndi kukonza magalimoto awa kumakhudza kwambiri magwiridwe antchito a injini, makamaka kutayika kwa chitsulo.

Pogwiritsa ntchito njira monga kuyatsa kapena kutenthetsa ndi magetsi kuti muchotse chozunguliracho, zimatha kupangitsa kuti chitsulo chitenthe kwambiri, zomwe zimapangitsa kuti maginito ayambe kuchepa komanso kuwonongeka kwa chotenthetsera pakati pa mapepala. Vutoli limachitika makamaka panthawi yokonza chozungulira ndi injini panthawi yopanga ndi kukonza.

Kulumikiza ma stacking welding ndi njira zina zingayambitsenso kuwonongeka kwa insulation pakati pa ma stacks, zomwe zimapangitsa kuti eddy current iwonongeke.

Kulemera kwa chitsulo kosakwanira komanso kukanikizana kosakwanira pakati pa mapepala. Zotsatira zake ndi zakuti kulemera kwa chitsulo chapakati sikokwanira, ndipo zotsatira zake zenizeni ndi zakuti mphamvu yamagetsi imaposa kulekerera, pomwe pakhoza kukhala mfundo yakuti kutayika kwa chitsulo kumaposa muyezo.

Chophimba pa pepala lachitsulo la silicon ndi chokhuthala kwambiri, zomwe zimapangitsa kuti dera la maginito likhale lodzaza kwambiri. Pakadali pano, ubale wapakati pa mphamvu yamagetsi yopanda katundu ndi magetsi umapindika kwambiri. Ichi ndi chinthu chofunikira kwambiri pakupanga ndi kukonza mapepala achitsulo a silicon.

Pakupanga ndi kukonza zitsulo zachitsulo, momwe chimagwirira ntchito cha silicon steel sheet punching ndi shearing surface attachment chingawonongeke, zomwe zingachititse kuti chitsulo chitayike kwambiri pogwiritsa ntchito maginito omwewo; Pa ma variable frequency motors, kutayika kwachitsulo kowonjezera komwe kumachitika chifukwa cha ma harmonics kuyeneranso kuganiziridwa; Ichi ndi chinthu chomwe chiyenera kuganiziridwa mokwanira pakupanga.

Kuwonjezera pa zinthu zomwe zili pamwambapa, kapangidwe ka kutayika kwa chitsulo cha injini kayenera kutengera kupanga ndi kukonza kwenikweni kwa chitsulo chapakati, ndipo kuyesetsa konse kuyenera kuchitidwa kuti kutsimikizire kuti mtengo wongopeka ukugwirizana ndi mtengo weniweni. Ma curve odziwika omwe amaperekedwa ndi ogulitsa zinthu wamba amayesedwa pogwiritsa ntchito njira ya Epstein square coil, koma njira ya maginito ya magawo osiyanasiyana mu injini ndi yosiyana, ndipo kutayika kwapadera kwachitsulo chozungulira sikungaganizidwe pakadali pano. Izi zingayambitse kusagwirizana kosiyanasiyana pakati pa mtengo wowerengedwa ndi woyesedwa.

Njira zochepetsera kutayika kwa chitsulo mu kapangidwe ka uinjiniya

Pali njira zambiri zochepetsera kugwiritsa ntchito chitsulo mu uinjiniya, ndipo chofunika kwambiri ndikusintha mankhwala kuti agwirizane ndi vutoli. Zachidziwikire, sikuti ndi kungogwiritsa ntchito chitsulo chokha, komanso kutayika kwina. Njira yofunika kwambiri ndikudziwa zifukwa zomwe zimapangitsa kuti chitsulo chitayike kwambiri, monga kuchuluka kwa maginito, kuchuluka kwa ma frequency, kapena kuchuluka kwa malo okhala. Zachidziwikire, mwanjira yachizolowezi, kumbali imodzi, ndikofunikira kuyandikira zenizeni pafupi momwe zingathere kuchokera kumbali yoyeserera, ndipo kumbali ina, njirayi imaphatikizidwa ndi ukadaulo kuti muchepetse kugwiritsa ntchito chitsulo chowonjezera. Njira yomwe imagwiritsidwa ntchito kwambiri ndikuwonjezera kugwiritsa ntchito mapepala abwino achitsulo cha silicon, ndipo mosasamala kanthu za mtengo wake, chitsulo cha super silicon chochokera kunja chingasankhidwe. Zachidziwikire, chitukuko cha ukadaulo watsopano woyendetsedwa ndi mphamvu zapakhomo chathandizanso chitukuko chabwino m'madera akumtunda ndi akumunsi. Makampani opanga zitsulo zapakhomo akuyambitsanso zinthu zapadera zachitsulo cha silicon. Mibadwo ili ndi gulu labwino la zinthu zosiyanasiyana zogwiritsidwa ntchito. Nazi njira zingapo zosavuta zokumana nazo:

1. Konzani dera la maginito

Kukonza bwino maginito, kuti ndikhale wolondola, ndiko kukonza sine ya mphamvu ya maginito. Izi ndizofunikira, osati kokha pa maginito okhazikika oyambitsa ma frequency. Maginito osinthika oyambitsa ma frequency ndi maginito ogwirizana ndi ofunikira. Pamene ndinali kugwira ntchito mumakampani opanga makina a nsalu, ndinapanga maginito awiri okhala ndi magwiridwe antchito osiyanasiyana kuti ndichepetse ndalama. Zachidziwikire, chinthu chofunikira kwambiri chinali kupezeka kapena kusakhalapo kwa mitengo yokhotakhota, zomwe zinapangitsa kuti mphamvu ya maginito ya mpweya isagwirizane. Chifukwa chogwira ntchito pa liwiro lalikulu, kutayika kwa chitsulo kumakhala kwakukulu, zomwe zimapangitsa kuti pakhale kusiyana kwakukulu pakati pa maginito awiriwa. Pomaliza, pambuyo powerengera pang'ono, kusiyana kwa kutayika kwa chitsulo kwa injini pansi pa njira yowongolera kwawonjezeka ndi kuwirikiza kawiri. Izi zimakumbutsanso aliyense kulumikiza ma algorithm owongolera popanga maginito osinthika olamulira liwiro.

2. Chepetsani kuchuluka kwa maginito

Kuonjezera kutalika kwa chitsulo chapakati kapena kuwonjezera dera la maginito la dera la maginito kuti muchepetse kuchuluka kwa maginito, koma kuchuluka kwa chitsulo chomwe chimagwiritsidwa ntchito mu injini kumawonjezeka moyenerera;

3. Kuchepetsa makulidwe a chitsulo kuti muchepetse kutayika kwa mphamvu yoyambitsidwa

Kusintha mapepala achitsulo a silicon opindidwa ndi moto ndi mapepala achitsulo a silicon opindidwa ndi ozizira kungachepetse makulidwe a mapepala achitsulo a silicon, koma zidutswa zachitsulo zopyapyala zidzawonjezera kuchuluka kwa zidutswa zachitsulo ndi ndalama zopangira injini;

4. Kugwiritsa ntchito mapepala achitsulo a silikoni ozungulira ozizira okhala ndi mphamvu yabwino ya maginito kuti achepetse kutayika kwa hysteresis;

5.Kugwiritsa ntchito chitsulo choteteza kutentha chapamwamba kwambiri;

6. Kutentha mankhwala ndi kupanga ukadaulo

Kupsinjika kotsala pambuyo pokonza chitsulo kumatha kukhudza kwambiri kutayika kwa injini. Pokonza mapepala achitsulo a silicon, njira yodulira ndi kupsinjika kwa kukanda kwa chitsulo zimakhudza kwambiri kutayika kwa pakati pa chitsulo. Kudula motsatira njira yozungulira ya pepala lachitsulo la silicon ndikuchita chithandizo cha kutentha pa pepala lachitsulo la silicon kungachepetse kutayika ndi 10% mpaka 20%.

Nthawi yotumizira: Novembala-01-2023