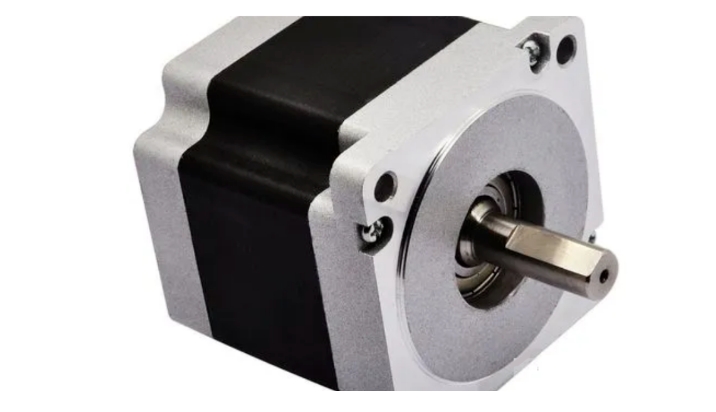

1. Chifukwa chomwe injini ya stepper ili ndi chochepetsera

Kuchuluka kwa kusintha kwa mphamvu ya stator phase mu mota ya stepper, monga kusintha kugunda kwa input kwa stepper motor drive circuit kuti iyende pa liwiro lotsika. Pamene mota ya stepper yotsika ikuyembekezera lamulo la stepper, rotor imakhala yoyima. Mukaponda pa liwiro lotsika, kusinthasintha kwa liwiro kudzakhala kwakukulu. Ngati isinthidwa kukhala ntchito ya liwiro lokwera, vuto la kusinthasintha kwa liwiro lingathe kuthetsedwa, koma torque sidzakhala yokwanira. Kuthamanga kotsika kungayambitse kusinthasintha kwa torque, pomwe kuthamanga kwambiri kumabweretsa torque yosakwanira, kotero chochepetsera chikufunika.

2. Kodi zochepetsera zomwe zimagwiritsidwa ntchito nthawi zambiri zama stepper motors ndi ziti?

Chochepetsera ndi gawo lodziyimira palokha lopangidwa ndi kutumiza giya, kutumiza nyongolotsi, ndi kutumiza nyongolotsi ya giya lomwe lili mkati mwa chipolopolo cholimba. Chimagwiritsidwa ntchito nthawi zambiri ngati chipangizo chochepetsera kutumiza pakati pa drive yoyambirira ndi makina ogwirira ntchito, zomwe zimagwira ntchito pofananiza liwiro ndi kutumiza torque pakati pa drive yoyambirira ndi makina ogwirira ntchito kapena actuator;

Pali mitundu yosiyanasiyana ya zochepetsera mphamvu, zomwe zingagawidwe m'magulu ochepetsera mphamvu zamagetsi, zochepetsera nyongolotsi, ndi zochepetsera mphamvu zamagetsi zapadziko lonse lapansi malinga ndi mtundu wa zotumizira; Malinga ndi magawo osiyanasiyana otumizira mphamvu zamagetsi, zitha kugawidwa m'magulu ochepetsera mphamvu zamagetsi a gawo limodzi ndi ambiri;

Malinga ndi mawonekedwe a magiya, amatha kugawidwa m'magulu ochepetsa magiya a cylindrical, ochepetsa magiya a bevel, ndi ochepetsa magiya a cylindrical a bevel;

Malinga ndi kapangidwe ka giya, imatha kugawidwa m'magulu ochepetsa mpweya osatsegulidwa, ochepetsa mpweya wogawanika, ndi ochepetsa mpweya wozungulira.

Zochepetsera mpweya zomwe zili ndi ma stepper motors zikuphatikizapo zochepetsera mpweya za planetary, zochepetsera mpweya wa nyongolotsi, zochepetsera mpweya wa parallel gear, ndi zochepetsera mpweya wa screw gear.

Kodi kulondola kwa stepper motor planetary reducer ndi kotani?

Kulondola kwa chochepetsera, chomwe chimadziwikanso kuti return clearance, kumachitika mwa kukonza mapeto otuluka ndikuzungulira mozungulira komanso motsutsana ndi wotchi kuti apange torque yovomerezeka ya + -2% torque kumapeto otuluka. Pakakhala kusuntha pang'ono kwa angular kumapeto olowera a reducer, kusuntha kwa angular kumeneku kumatchedwa return clearance. Unit ndi "arc minute", yomwe ndi gawo limodzi mwa makumi asanu ndi limodzi a digiri. Mtengo wamba wa return clearance umatanthauza mapeto otuluka a gearbox.

Chotsitsa cha planetary cha stepper motor chili ndi makhalidwe monga kulimba kwambiri, kulondola kwambiri (mpaka mfundo imodzi pa siteji), mphamvu yotumizira ma transmission (97% -98% pa siteji), chiŵerengero chapamwamba cha torque/voliyumu, komanso chosasamalira.

Kulondola kwa kutumiza kwa mota ya stepper sikungasinthidwe, ndipo ngodya yogwirira ntchito ya mota ya stepper imatsimikiziridwa kwathunthu ndi kutalika kwa sitepe ndi nambala ya pulse. Nambala ya pulse ikhoza kuwerengedwa kwathunthu, ndipo palibe lingaliro la kulondola mu kuchuluka kwa digito. Sitepe imodzi ndi sitepe imodzi, ndipo sitepe yachiwiri ndi masitepe awiri.

Kulondola komwe kwakonzedwa bwino pakadali pano ndi kulondola kwa kubweza kwa giya kwa bokosi la gearbox lochepetsa magiya la planetary:

1. Njira yosinthira kulondola kwa spindle:

Kusintha kwa kulondola kwa kuzungulira kwa spindle yochepetsera mapulaneti nthawi zambiri kumatsimikiziridwa ndi bearing ngati cholakwika cha machining cha spindle yokha chikukwaniritsa zofunikira.

Chofunika kwambiri pakusintha kulondola kwa kuzungulira kwa spindle ndikusintha malo operekera bearing. Kusunga malo oyenera operekera bearing ndikofunikira kwambiri pakugwira ntchito ndi moyo wa zinthu zoperekera bearing.

Pa ma bearing ozungulira, pamene pali mpata waukulu, katunduyo samangoyang'ana pa chinthu chozungulira chomwe chikupita ku mphamvu, komanso amayambitsa kupsinjika kwakukulu pakukhudzana pakati pa njira zamkati ndi zakunja za bearing, kufupikitsa moyo wa bearing, ndikusuntha mzere wapakati wa spindle, zomwe ndizosavuta kuyambitsa kugwedezeka kwa zigawo za spindle.

Chifukwa chake, kusintha kwa ma rolling bearing kuyenera kuyikidwa kale kuti pakhale kusokoneza kwina mkati mwa bearing, motero kupanga kuchuluka kwa elastic deformation pakukhudzana pakati pa chinthu chozungulira ndi njira zamkati ndi zakunja, motero kukonza kuuma kwa bearing.

2. Njira yosinthira mipata:

Chochepetsera mapulaneti chimayambitsa kukangana panthawi yoyenda, zomwe zimapangitsa kusintha kwa kukula, mawonekedwe, ndi mawonekedwe a pamwamba pa ziwalozo, komanso kuwonongeka, zomwe zimapangitsa kuti malo olumikizirana pakati pa ziwalozo akwere. Pakadali pano, tifunika kusintha mkati mwa malo oyenera kuti tiwonetsetse kuti kuyenda pakati pa ziwalozo ndi kolondola.

3. Njira yobwezera zolakwika:

Chochitika chothetsa zolakwika za ziwalo zokha panthawi yogwira ntchito kudzera mu msonkhano woyenera kuti zitsimikizire kulondola kwa njira yoyendetsera zida.

4. Njira yokwanira yolipirira:

Gwiritsani ntchito zida zomwe zayikidwa pa chochepetsera chokha kuti muwonetsetse kuti makinawo asinthidwa bwino komanso kusinthidwa pa benchi yogwirira ntchito, kuti muchotse zotsatira zonse za zolakwika zosiyanasiyana zolondola.

Nthawi yotumizira: Novembala-28-2023